DB Group has launched a three-year restructuring program for the modernization of the company. S3 means that we will be modernizing DB Group in the three key areas of action by the end of 2027: infrastructure, rail operations and profitability. The aim is to restore the efficiency of rail, significantly improve the customer experience and secure DB Group’s financial viability. In short: we want to become more punctual, more reliable and more profitable.

Back on track with S3

The success of S3 is measured in terms of clearly defined targets

1.Improving

infrastructure

Turning the tide in infrastructure

- Swift modernization of the existing infrastructure (in particular facilities renewal, reduction in restricted speed sections, general modernizations, interlocking programs, small and medium-sized measures, stations of the future).

2024: 5,998

2.Improving

operations

Stabilizing punctuality

- Introducing a synchronized construction system for schedule optimization.

- Reducing overloaded routes and hubs to stabilize operations.

- Improving vehicle quality.

2024: 62.5%

3.Improving profitability

Securing financial viability

- Improving staff productivity.

- Adjusting ramp-ups of capital expenditures.

- Business model transformation at DB Long-Distance and DB Cargo.

- Increasing profitability at DB Regional.

2024: € –0.3 billion

1. Improving

1. Improving

infrastructure

Turning the tide in infrastructure

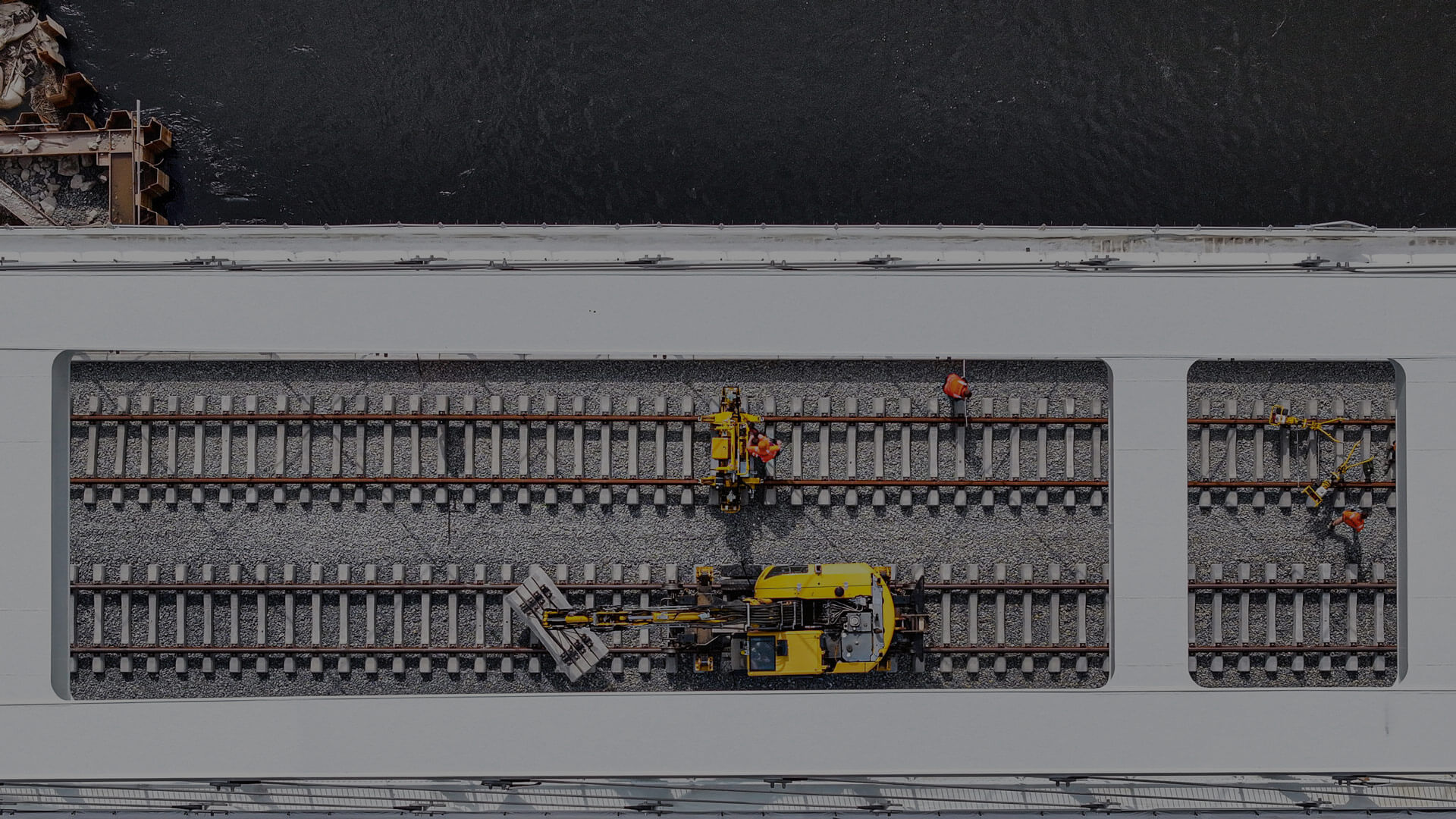

The infrastructure pillar focuses on modernizing the existing infrastructure – including the modernization of the high-performance corridors and the other parts of the network as well as interlockings. In addition, we will make 300 more stations more customer-friendly and fit for the future between 2025 and 2027. More than 100 stations were already converted in 2024. Furthermore, so-called small and medium-sized measures such as additional track change facilities provide greater capacity. This will help DB Group to restore the performance of its infrastructure within three years and return to its growth path.

How do we want to achieve this?

- Pressing ahead with general modernizations.

- Replacing the components most susceptible to faults and thus reducing the number of restricted speed sections.

- Replacing interlocking technology that is in need of renewal and labor-intensive.

- Realizing rapid capacity gains.

Highlight 2024The first general modernization was implemented with the Riedbahn

With the Riedbahn, the first general modernization of the highly utilized network was completed on schedule in 2024. With well over 300 long-distance, regional and freight trains every day, the Riedbahn is one of the busiest lines in the German rail network. DB InfraGO modernized the facilities on the 74 km line between Frankfurt am Main and Mannheim within a closure period of five months. New tracks, switches, signals and interlocking technology will ensure stable operations in the future, while passengers will benefit from modern and attractive stations of the future. Rerouting and substitute services brought passenger and freight transport customers reliably to their destinations during construction work. The modernization has the potential to reduce operational disruptions by up to 80%. This will have positive effects for the entire rail network in Germany on account of the central location and very high capacity utilization of the Riedbahn.

Making it happen:

the Riedbahn team

» The Riedbahn has shown us that we are capable of achieving great things. Completely modernizing a route in five months – nothing like this has ever been attempted before. The fact that it was successful gives everyone involved a great deal of confidence for further corridors.«

Gerd-Dietrich Bolte,

Head of Infrastructure Projects, Central Region

What have we already achieved in 2024?

- Complete modernization of the fault-prone Riedbahn in just five months.

- Passengers and goods transported to their destination via a substitute concept.

- Thanks to team spirit and strong partners, the general modernization concept is working.

Significant reduction in restricted speed sections

The number of restricted speed sections is to be reduced by 30% compared to 2024. In particular, this is to be achieved by avoiding the proliferation of restricted speed sections and quickly eliminating them, both in the high-performance network and the other parts of the network, in order to reach a level of fewer than 200 restricted speed sections per year on average in the overall network. This will make a significant contribution to stabilizing the overall system and the quality of operations.

What have we already achieved in 2024?

- A reversal of the trend for restricted speed sections on highly utilized routes.

- We are also below the previous year’s level across the overall network.

- This trend is set to continue with additional prevention programs and innovative methods for eliminating restricted speed sections.

Replacement of old interlocking technology

Interlocking technology ranks among the most quality-critical technologies with the highest obsolescence. It is also critical for trouble-free, efficient and safe rail operations. Interlocking programs therefore aim to replace outdated and personnel-intensive interlocking technology. This reduces personnel intensity in operation and maintenance and eliminates bottlenecks in the supply of spare parts. DB InfraGO plans to replace 50 old interlockings in 2025.

What have we already achieved in 2024?

- Project scope specified for the “replacement of old interlockings” program.

- Interlocking projects for 2025 evaluated with regard to the quantity of old interlockings to be replaced and implementation initiated.

2. Improving

2. Improving

operations

Significant improvement in quality of operations

To ensure that the schedule is stabilized even in the event of rising construction volumes, DB InfraGO intends to completely reorganize the construction and driving system: in the future, construction will follow the schedule rather than the schedule following construction as previously. As a result, the construction and maintenance system is being transformed by DB InfraGO into a synchronized construction and maintenance system. In addition, we will take action on hubs and lines to reduce congestion and improve vehicle quality.

How do we intend to achieve this?

- Roll out the synchronized construction system network-wide and for all maintenance and capital expenditure stages.

- Reduce overloading in the system by taking appropriate measures.

- Consistently improve vehicle quality in terms of punctuality and comfort.

Construction and driving in better harmony

Construction in sync aims to resolve the conflict between driving and construction and ensure that operations are stabilized despite persistently high construction requirements. Construction in sync means introducing a synchronized production standard for maintenance and renewal measures in the existing network in the form of standardized closure periods: the so-called closure period container approach. This approach is the prerequisite for reconciling the required construction volume with stable and, above all, timely communicated schedule conditions.

What have we already achieved in 2024?

- The first maintenance containers have been in use since July 2024.

- More than 80% of the maintenance work was performed in the second half of 2024 on the routes with maintenance containers in line with the cycle times.

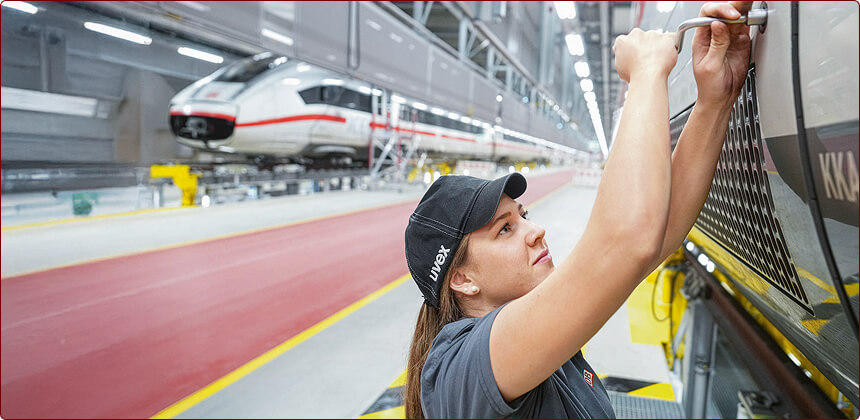

Further increase in vehicle quality

Improving vehicle quality helps to reduce vehicle-related train cancellations, increase availability and contribute to greater punctuality and an improved passenger experience. Through a “younger” fleet and maintenance optimization, we have reduced punctuality-related vehicle disruptions and improved vehicle availability. The passenger experience is also getting better: thanks to robust components and optimized maintenance, our passengers experience fewer comfort disruptions with regard to air-conditioning, on-board catering, toilets and seat reservation displays.

How do we intend to achieve this?

- Fleet modernization and rejuvenation.

- Optimization of components to resolve recurring faults.

- Expansion of existing ICE maintenance depots and construction of an additional depot.

3. Improving

3. Improving

profitability

Significant increase in efficiency

The profitability pillar involves returning our business to profitability and thus securing the financial viability of DB Group in the long term. Many areas of DB Group’s business operations are in the red, in part due to the quality crisis in infrastructure and operations. We intend to systematically steer the restructuring process using key economic indicators such as EBIT, personnel expenses and debt coverage. Modernizing infrastructure and operations makes a significant contribution to improving profits.

How do we intend to achieve this?

- Reduction in personnel expense ratio.

- Business model transformation at DB Long-Distance and DB Cargo.

- Improved profitability at DB Regional.

Active personnel management

To make the S3 restructuring program a success, we are consistently focusing on the modernization of processes and workflows and on increasing staff productivity. With this in mind, we want to sustainably reduce our personnel requirements, especially with regard to overheads. To reduce our workforce by at least 10,000 by 2027, we are relying on natural fluctuation and instruments such as severance payments, part-time work leading up to retirement and bonuses for changing positions. DB Group needs to secure its long-term performance capability. To this end, we will continue to bring many new employees on board – especially in operational and customer-facing areas. As an employer in Germany, we continue to be very attractive, as shown by the more than 600,000 applications for vacancies in 2024.

What have we already achieved in 2024?

- Full Functioning program to strengthen our executives’ transformation skills.

- About 6,100 young talents were hired, whom we train in 50 professions and 25 dual study programs.

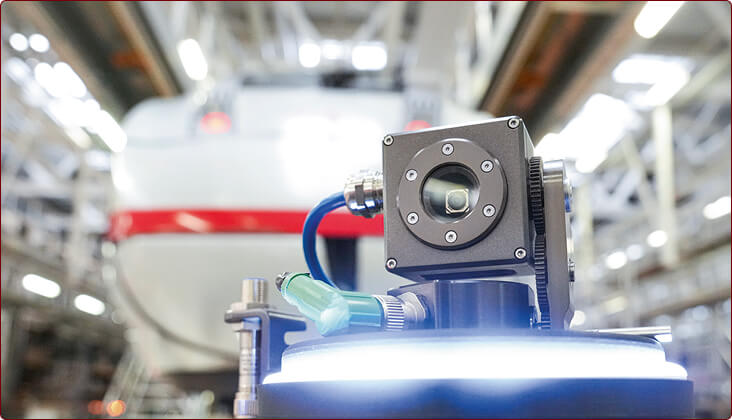

Further expansion of digitalization

Digitalization and technical innovations are key to achieving the targets of the S3 restructuring program. They improve profitability and ensure more stable operations. Artificial intelligence (AI) is used in various projects to predict arrival times and intelligently control train services. Sensors on the vehicle, on the track or the depots automatically collect data on the condition of vehicles or components and help to efficiently plan the time spent in the depot. To overcome the challenges of the IT landscape, systems and applications are centralized, standardized and consolidated. This reduces costs and improves the performance of the overall system. The aim is to provide reliable and consistent information across all information channels, especially in the event of disruptions.

Key digitalization measures:

- Further develop passenger information reliably and consistently.

- Stabilize operations with the help of AI.

- Use digital vehicle maintenance to get trains back on track faster.

- Strong IT for greater economic efficiency.

We are focusing on a new travel experience by 2027: significantly more punctual trains, modernized stations and a high-performance rail network for a first-class travel experience.