Management approach and targets

In the track infrastructure, there is a very high demand for resources in our upstream value-added chain, particularly as a result of our construction activities. We aim to establish a circular economy by 2040, with a particular focus on Germany. For us, circular economy means using raw materials sparingly, keeping them in the value-added chain for as long as possible and – where technically and legally possible – recycling our waste in order to reduce the need for primary raw materials and the volume of waste. This means that technically necessary primary raw materials still flow into the input and waste is recycled in the output, provided this is legally and technically possible. This also contributes to a reduction in our Scope 3 emissions.

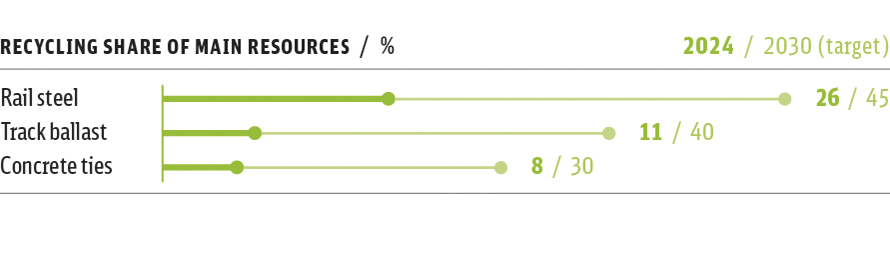

We require large quantities of materials for the maintenance and expansion of our infrastructure – mainly rail steel, track ballast and concrete ties. Our demand for the primary raw materials required for this contributes to the consumption of non-renewable resources. According to our own analysis, these three main resources account for about 75% of the weight of our total material input (in DB Group in Germany). We want to significantly increase the share of recycled materials in the coming years and have set ourselves binding targets for 2030 compared to the base year 2019:

- Rail steel: from 25% to 45%

- Track ballast: from 13% to 40%

- Concrete ties: from 6% to 30%

We also want to maintain our recycling rate at a very high level of at least 95%. In the construction and maintenance of our track infrastructure in particular and related to our vehicle fleet, we produce waste that contains valuable resources such as metals and mineral building materials. Most of these are already being recycled today and are, therefore, still available to the economic cycle.

We use internal material flow accounting to document and evaluate the resources used on an annual basis. We are initially concentrating on the accounting of ballast, concrete, steel, copper and aluminum for DB Group in Germany and thus on our core business. The volumes of resources are recorded in the input and output for the respective year under review. Here, we focus on the construction of track infrastructure and rolling stock as well as vehicle replacement parts. We will gradually transfer our material flow accounting to our digital resource inventory from 2025. To that end, we collect manufacturer-specific product and material data to gradually create holistic resource transparency for the core business of DB Group in Germany.

We are expanding and intensifying our cooperation with suppliers to drive the development of recycled and recyclable products. Thanks to our active involvement in national and international associations and committees such as the Federal Association of German Industry (BDI), the International Union of Railways (UIC) and the German Center for Rail Transport Research (DZSF), we are already networked with various players in the field of circular economy. As part of our long-standing partnership with the construction industry and planners in the Future Initiative for Rail Construction (Zukunftsinitiative Bahnbau; ZIB), we are involved in the “Green Planning, Construction and Operation”ZIB cluster. In a joint declaration, ZIB 2024 acknowledged its responsibility for achieving the climate protection targets in accordance with the Paris Agreement.

Modernization is one lever on the way to climate-friendly construction, as it uses fewer raw materials and saves CO₂e emissions compared to new builds. In 2024, the modernization of bridges No. 42 was considered as a measure for climate and resource protection as part of ZIB. There are currently about 5,800 vaulted bridges on the DB rail network. In the past, smaller vaulted bridges, in particular, were usually demolished at the end of their service life and replaced with a completely new concrete frame structure. DB InfraGO and the TU Dresden have jointly developed a process for the modernization and maintenance of these bridges. The first smaller single-arch vaulted bridges in DB Group’s portfolio have already been modernized. The modernization of the vaulted bridge near Müggenburg on the rail line from Ihrhove to Groningen began in July 2024.