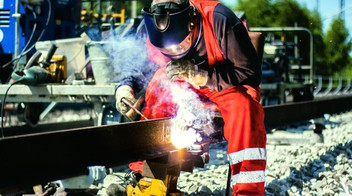

Digitalization and innovation

DB Cargo has developed a comprehensive digitalization and automation strategy. The target is to provide customers with easier access to the rail system and more transparency about shipment status, as well as to significantly speed up processes in rail transport, such as train formation and maintenance. The following selected measures help to achieve this:

- DB Cargo is developing Germany’s first digital freight station in the Munich-North marshaling yard. Capacity is to be increased by up to 40% through largely automated train handling. In addition, DB Cargo is testing automated freight car diagnosis with AI, and the automated brake probe and the automated shunting locomotive with partners from science and industry.

- An important project is the DAC. DAC simplifies the coupling of freight cars and the brake test: the cars are pushed together by a locomotive and connect automatically. Mounting the coupling and the time-consuming running down the hump of the train is eliminated. Thanks to automation and digitalization, train composition is becoming faster and is revolutionizing rail freight transport. Important operational knowledge is collected through the test train financed by the BMDV as part of the DAC4EU project. As a next step, the basis for the introduction of DAC must now be laid at European level. Through the European Union’s rail transport research and innovation partnership (Europe’s Rail Joint Undertaking), the sector currently identifies up to 100 existing commercial train connections, the locomotives and freight cars of which are to be fitted with DAC. These pilot trains are to test the functions of DAC in practice in order to prepare for the nationwide rollout of the technology. The first commercial pilot trains with DAC shall run in Europe from the end of 2026.