Production and technology

If the production quality of passenger transport services (in particular punctuality) suffers, this has an impact on service quality and can lead to the loss of customers. For our rail freight transport customers, too, punctuality is a key factor when selecting a mode of transport.

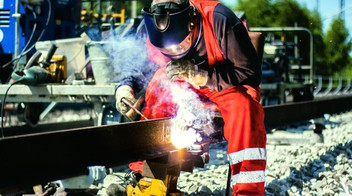

Due to the state of infrastructure, or as a result of unknown weaknesses in the condition of facilities, the need for unplanned maintenance measures (e.g. ad hoc repair of bridges or replacement of damaged concrete ties) cannot be ruled out. This can lead to higher costs and restricted speed section.

The availability, capacity and the condition of the track infrastructure are significant prerequisites for a competitive rail transport. In order to ensure that rail remains ready for the future in the long term, it is also necessary to digitalize and automate the infrastructure. The intensity of use on the German rail network has increased significantly. The capacity of the track infrastructure has not been expanded in line with growing demand. At the same time, the condition of the infrastructure has deteriorated. Construction is being carried out at a very high level in order to drive modernization. However, this construction work requires the sacrifice of additional capacity while the work is in progress. As capacity utilization increases, the effects of traffic jams and delays are increasing exponentially. The intensity of construction activity in the network has already increased noticeably and is expected to continue to increase. This can also have a strong impact on the carriers’ schedules and production quality, some of which cannot be compensated for. As a result of the implementation of the extensive general modernizations planned from mid-2024, performance and revenue burdens may occur beyond the extent included in the planning. In addition, further expense risks may arise as part of the implementation process.

The range and quality of our services depend to a significant extent on the availability and reliability of the production resources used, intermediate services procured and the quality of our partners’ services. We therefore maintain an intense dialog with our suppliers and business partners on the subject of quality. This is of particular importance in the vehicle industry. Postponed deliveries of new vehicles may result in revenue losses and additional expenses, for example, due to rail replacement services or penalty payments.

Sufficient availability of our vehicle fleet is particularly critical. Significant restrictions endanger operating schedules. In regional transport, there is the additional risk of penalties if trains are canceled or punctuality is insufficient. We try to minimize this risk by taking preventative actions and also by minimizing the consequences should it happen, such as by providing replacement vehicles or by organizing replacement services.

The technical production resources used in rail transport must comply with applicable standards and requirements, which are subject to change. As a result, we may receive technical complaints concerning our vehicles. This leads to the risk that we may only be permitted to use individual series or rail car types under certain conditions, such as limited speeds, shorter intervals between maintenance or reduced wheel set loads, or not at all. In addition, we cannot accept new vehicles that have defects or for which the necessary vehicle certification has not been granted. As a result of technical defects or conditions, vehicles may need to be refitted, which could lead to significant restrictions on availability or even temporary prohibition of use.

In regional transport, a risk can arise from the redundancy of vehicles following the expiry or re-tendering of a transport contract. As a countermeasure, alternative possible uses are investigated.

Increasing digitalization means that dependence on secure IT that is available around the clock is increasing. This results in IT, telecommunications and cyber risks such as the interruption of the availability of IT/OT systems, which can lead to serious business interruptions, or the unauthorized access of third parties to customer data.

We combat these risks through forward-thinking IT security management, which provides the necessary security for our IT-based business processes. A key instrument here is risk management for information, IT applications, and IT infrastructure and services. The relevant risks are identified, analyzed, evaluated and reduced. The remaining risks are documented and, if necessary, reported to and monitored by suitable bodies. Our information security management follows international standards such as ISO 27001/27002:2022 and industry-specific standards.

In order to minimize critical technical vulnerabilities, numerous countermeasures (such as firewalls, encryption, appropriate network segmentation and prompt software updates) have been implemented. Appropriate redundancy of the IT systems (including across several locations) increases the overall resilience of critical business processes, applications and infrastructures. The network and cloud infrastructure also has a redundant design, where required, for the purposes of IT security and business continuity.

For the most important processes and IT applications, systematic and regular penetration tests and red-team stress tests are carried out in order to detect and eliminate weak points at an early stage.

Overall, these measures reduce the risk of attacks, the resulting outages of IT/OT systems, the disruption of communications and the theft of confidential information.

Irregularities, such as customs offenses and theft, can occur in freight transport. We combat this, among other things, by involving qualified customs coordinators and using an immediate reporting system for tax assessment notices.