Recycling rate – output resource management

Within the scope of our environmental management system in accordance with DIN ISO 14001, clear regulations regarding the circular economy have been defined for the Integrated Rail System in Germany. For example, when materials and substances are no longer needed, we check whether they can be recycled and how they leave DB Group. We are basically a waste producer, which means that we control and take active responsibility for implementing legally compliant and environmentally friendly waste disposal via third parties all the way through to final disposal. The contractual design and management of external disposal services is carried out centrally for the Integrated Rail System by Procurement. Specialist waste disposal companies are appointed that have the appropriate waste-related management and economic expertise in accordance with section 56 (2) of the Circular Economy Act (Kreislaufwirtschaftsgesetz; KrwG). All waste generated in the Integrated Rail System that is fed into waste disposal in accordance with existing disposal agreements or within the scope of the municipal supply obligation applicable in Germany is taken into account.

Using our internal waste management system, we record and dispose of almost every type of waste separately according to individual fractions. This allows us to recirculate the waste and generate income from specific waste. Hazardous and non-hazardous waste is recorded via a central IT system, which provides transparency about waste flows and disposal routes. A core principle of DB Schenker’s extensive global environmental management system is that the relevant locally applicable legal regulations for waste disposal are complied with as a minimum requirement. Corresponding contractual provisions are made and monitored at a local level.

waste (total) and recycling rate | 2023 | 2022 | Change | 2021 | |

absolute | % | ||||

Waste (total) (thousand t) | 7,974 | 8,187 | –213 | –2.6 | 8,830 |

Recycling rate (%) | 96.5 | 96.7 | –0.2 | – | 96.2 |

Period from October 1 to September 30; DB Schenker January 1 to December 31 of the previous year.

Individual figures are rounded and therefore may not add up. DB Cargo AG is the only part of the DB Cargo business unit included. The waste has been generated through company activities and is managed by third parties outside DB Group.

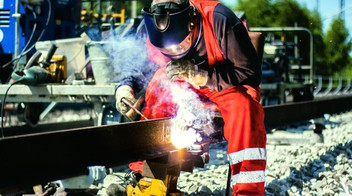

In 2023, we again maintained our recycling rate at a high level of over 95%. Especially in the construction and maintenance of our track infrastructure and related to our vehicle fleet, we produce waste that contains valuable resources such as metals and mineral building materials. These are already predominantly recycled and continue to be available to the economic cycle.

Using products as long as possible makes an important contribution to greater resource conservation and offers the opportunity to avoid waste and extend resource cycles. We are extending the service life of our trains, for example, through continuous maintenance and modernization (redesign). If DB Group still has to discard a vehicle, it is either resold or components that can still be used are removed and the rest of the vehicle is sent for recycling. DB Cargo’s used train portal, for example, will sell saleable rolling stock on the market. DB Regional operates an online platform for the sale of used vehicles for our buses.

When we build a new tunnel or otherwise intervene in an area, we transport large quantities of excavated material from the earth. We return the many tons of sand, gravel, clay and natural stone to the cycle. With Erdpool, our new digital marketplace, we can offer materials for sale even before the start of a construction project. This means that the raw materials can be used elsewhere. Marketing not only reduces the degradation of valuable mineral raw materials, but also reduces the use of waste disposal capacity. Erdpool also ensures that the excavated and breaking material is inspected in accordance with the applicable environmental requirements.

waste according to type of waste and disposal procedure / thousand t | 2023 | 2022 | 2021 |

Construction waste | 7,493 | 7,657 | 8,342 |

Recycling | 7,272 | 7,449 | 8,069 |

Thermal utilization and disposal | 221 | 208 | 273 |

Scrap | 321 | 363 | 327 |

Recycling | 320 | 362 | 327 |

Thermal utilization and disposal | 0.3 | 0.2 | 0.1 |

Electronic scrap | 1.4 | 1.3 | 3.8 |

Recycling | 1.1 | 0.9 | 3.3 |

Thermal utilization and disposal | 0.3 | 0.4 | 0.5 |

Municipal waste and plastic | 64.2 | 71.1 | 55.3 |

Recycling | 35.4 | 37.8 | 23.7 |

Thermal utilization and disposal | 28.8 | 33.3 | 31.6 |

Paper | 31.2 | 32.6 | 37.9 |

Recycling | 29.2 | 31.0 | 37.2 |

Thermal utilization and disposal | 1.9 | 1.6 | 0.7 |

Waste oil | 2.6 | 2.0 | 1.7 |

Recycling | 2.2 | 1.8 | 1.4 |

Thermal utilization and disposal | 0.3 | 0.1 | 0.2 |

Other 1) | 60.9 | 61.0 | 61.7 |

Recycling | 32.4 | 32.8 | 32.5 |

Thermal utilization and disposal | 28.5 | 28.2 | 29.2 |

Total waste | 7,974 | 8,187 | 8,830 |

Recycling | 7,693 | 7,916 | 8,495 |

Thermal utilization and disposal | 281 | 272 | 335 |

Period from October 1 to September 30; DB Schenker January 1 to December 31 of the previous year. Individual figures are rounded and therefore may not add up. DB Cargo AG is the only part of the DB Cargo business unit included. The waste has been generated through company activities and is managed by third parties

outside DB Group.

1) For example paint, varnish, sludge and other maintenance-related waste.

- In 2023, the volume of waste was close to the previous year’s level. At about 94%, the largest share was once again generated by construction waste. The recycling rate was 96.5%. By using targeted measures, such as selective decommissioning and contractual commitments to sorting and recycling facilities, we kept the share of recyclable waste high and the share of waste to be disposed of or incinerated at a very low level.

- Waste for incineration is always sent for thermal waste treatment. The energy released during burning is used as electrical energy, heat and/or process steam.

- Municipal waste only accounts for a small proportion of our total waste generation, but it is the most visible fraction in our trains and stations. We continued our approach to disposing of mixed municipal waste, with the target of recycling as much of the recyclable material contained therein as possible. We send all recyclable municipal waste to modern pre-treatment plants for sorting, so that at least 85% of the recyclable materials contained therein are cleanly separated for recycling.

hazardous and non-hazardous waste / thousand t | 2023 | 2022 | 2021 |

Hazardous waste | 378 | 385 | 477 |

Share of recycling (%) | 61.7 | 62.0 | 67.9 |

Share of thermal utilization and disposal (%) | 38.3 | 38.0 | 32.1 |

Non-hazardous waste | 7,596 | 7,802 | 8,352 |

Share of recycling (%) | 98.2 | 98.4 | 97.8 |

Share of thermal utilization and disposal (%) | 1.8 | 1.6 | 2.2 |

Total waste | 7,974 | 8,187 | 8,830 |

Period from October 1 to September 30; DB Schenker January 1 to December 31 of the previous year. The waste has been generated through company activities and is managed by third parties outside DB Group. Individual figures are rounded and therefore may not add up. DB Cargo AG is the only part of the DB Cargo business unit included.

Of the waste generated in 2023, about 95% (previous year: 95%) was classified as non-hazardous. This includes, for example, municipal waste and the majority of construction waste. The remainder, about 5%, includes waste that presents a risk to health or the environment – for example waste oil or contaminated waste wood. Special procedures ensure that this waste is disposed of safely. Here, too, we consider the conservation of resources and look at opportunities for recycling or thermal utilization of waste.