DB Vehicle Maintenance

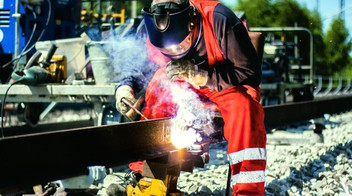

DB Vehicle Maintenance specializes in the field of heavy, safety-relevant maintenance and repairs to rolling stock and their components.

- New maintenance depot: The new ICE maintenance depot in Cottbus was built in less than 20 months, a record speed. State-of-the-art technology and automation at the depot ensure that work processes are simpler and more efficient, speeding up maintenance processes and reducing the workload on employees. For example, employees are able to identify parts and components with an app and order them to their work location on the train. About 1,200 jobs and apprenticeships will be created as a result.

- 3D printing: DB Group has reached the milestone of 100,000 spare parts produced using 3D printing technology. The 100,000th part is a gear housing for shunting locomotives. With a volume of just under 1 m³ and a weight of 570 kg, it is also the largest and heaviest 3D-printed part used by DB Group.

- DB Vehicle Maintenance put more than 100 Vectron electric locomotives into operation for Siemens Mobility before delivery to customers. Dessau is the most advanced locomotive test center in Europe, where multisystem tests can also be carried out.