Alternative drives and fuels

Our measures, analyses and testing in the area of green technologies also include alternative drives. These are low-emissions alternatives to pure diesel drives. Our target is, for example, to stop all diesel buses by 2038.

The use of alternative fuels is another way to achieve climate neutrality. To do this, we use our advanced TrainLab in which we are testing new railway transport technologies.

In numerous projects and initiatives, we test possible implementation variants for their practicality, in some cases together with partners:

- Hydrogen drive: We have concluded a framework agreement with the Portuguese manufacturer Caetanobus on the delivery of 60 hydrogen buses by 2026. On one full tank of hydrogen, the vehicles can travel between 350 km (in winter) and 550 km (in summer). Autokraft currently has two previous versions of the ordered buses in use.

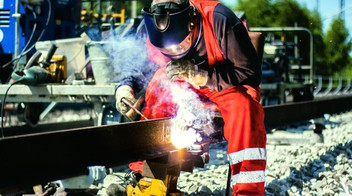

- Ammonia hydrogen engine: In 2023, we successfully conducted the first test stand tests with an ammonia hydrogen engine. The correspondingly re-equipped engine was able to provide several hundred hours of operation under full load using ammonia and hydrogen. In the next step, the tests are carried out with a higher-performance class motor in order to be able to continue in a rail vehicle in the future.

- Overhead wire islands for battery-powered trains: The so-called catenary islands, the construction of which are to be completed in Schleswig-Holstein by 2024, are a further step in the diesel phase-out. Battery-powered trains are able to run completely electrically on partially electrified lines because they are charged on overhead wire islands.

- Innovative charging station: With a new stationary charging station, DB Energy, Erzgebirgsbahn and the SRCC railway research campus at the Annaberg-Buchholz site want to drive the shift towards battery-powered trains. The target is to charge battery-powered trains on non- electrified lines during station stops. This requires an interface to the general German power grid and it must be ensured that the grid is not overloaded when charging the trains. The wallbox for trains will be tested for one year, and should be available for regular operation from 2024.

- Modern depot for e-buses: A new, modern depot for DB Group’s largest connected e-bus fleet opened in Frankfurt am Main at the end of June 2023. Twenty-seven new electric buses can be charged at a total of 20 charging points, with 100% eco-power. All the roofs of the depot are equipped with photovoltaic systems. The electricity generated from these flows directly into DB’s power grid.

- H2goesRail: As part of the H2goesRail project, DB Group is testing solutions for the use of green hydrogen and is working together with Siemens Mobility on an innovative complete hydrogen system consisting of supply infrastructure, train and maintenance infrastructure. We have developed a new method which, for the first time, means that a hydrogen train can be refueled at the same speed as a diesel train. DB Regional will test the new drive in the Mireo Plus H hydrogen train and the DB Energy fast filling system in 2024.

- Biofuel HVO: We are investing in green technologies, for example in the scaled use of the biofuel HVO (hydrotreated vegetable oil). The HVO used by DB Group is produced exclusively from biological residues and waste materials. Compared to conventional diesel it produces about 85% to 90% fewer accounted greenhouse gas emissions depending on the composition of the raw material.

- In 2023, we expanded our use of HVO in rail transport and a total of 13.7 million l (previous year: 2.7 million l) of HVO was used by DB Regional Rail, DB Cargo in Germany and DB Long-Distance. Throughout Germany, the availability of HVO at rail filling stations has been expanded from 5 to 14 filling stations as part of the starter package for diesel phase-out. Since April 2023, for example, the conversion of the filling station at the Munich North marshaling yard to HVO has saved about 9,000 t CO₂e per year.

- By the end of June 2024, about 1,800 t CO₂e will have been saved as part of a pilot project on the Southeast Bavaria Railway (Südostbayernbahn) through the use of about 650,000 l HVO.