Management approach and targets

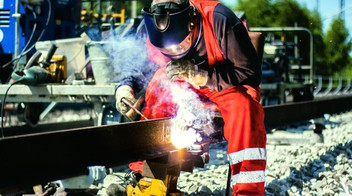

Our construction activities in particular mean that there is a very high demand for resources in the track infrastructure. As part of various formats of our stakeholder dialogue, we therefore also provide information on our targets, measures and progress in the area of resource conservation.

For us, resource conservation means we need to use raw materials carefully, keeping them in the value chain for as long as possible and recycling our waste whenever possible. We are striving to achieve a complete, circular economy throughout DB Group by 2040, with a special focus on the Integrated Rail System. Our particular focus is on our main resources: track ballast, concrete ties and rail steel, which represent about 80% of the weight of total material used in the Integrated Rail System. Here, we have set binding targets and will increase recycling shares by 2030 compared to the base year 2019:

- Rail steel: from 25% to 45%

- Track ballast: from 13% to 40%

- Concrete ties: from 6% to 30%

We also want to maintain our recycling rate at a very high level of at least 95%. In order to drive the development of recycled and recyclable products, we are expanding and intensifying our cooperation with suppliers. Through our active involvement in national and international associations and committees such as the BDI, Eurospec and the UIC, we have already networked with various players on the topic of circular economy.

As part of our multi-year partnership-based cooperation with the construction industry and planners in the railway construction future initiative (ZIB), we set up a new cluster ZIB “Green Planning, Construction and Operation” in 2023. An inventory has taken place in which potentials for measures and processes to improve climate protection and resource conservation have been identified. We want to make use of these opportunities in the short term, in particular through the use of recycled construction materials or the modernization of structures through preventive maintenance strategies instead of demolition.

With a material current balance sheet, we document and assess annually the resources that enter the operation and those that go back. We will initially concentrate on our main resources – ballast, concrete, steel, copper and aluminum – for the Integrated Rail System. The weight volumes of resources are recorded in the input and output for the respective year under review. Here, we focus on the construction of track infrastructure and vehicles as well as vehicle replacement parts. From 2024, we will gradually transfer our material current balance to our resource inventory, which is currently in development.